Features

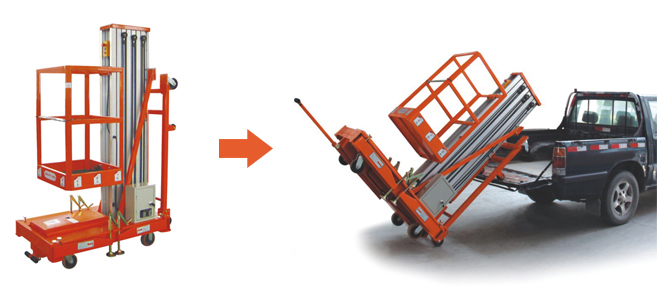

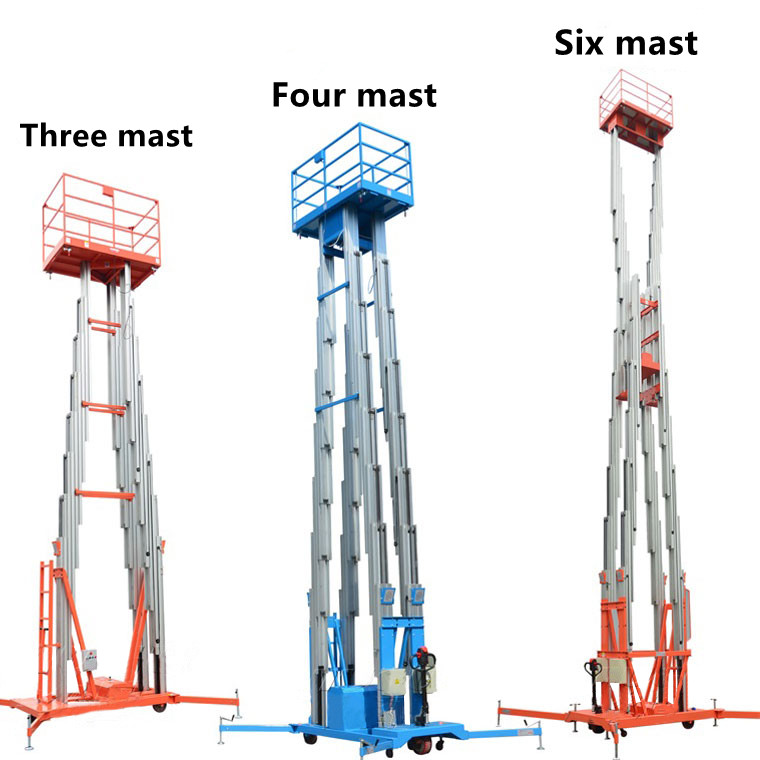

Using high-strength, high-quality aluminum alloy material, it has the advantages of beautiful appearance, small size, light weight, stable lifting, safety and reliability. Its light appearance can exert the highest lifting capacity in a very small space. The column lifting system has the characteristics of large capacity, strong stability, large platform area and convenient implementation. We supply five types of aluminum alloy lift Single-column aluminum alloy lift: This series of products is indoor type, widely used in high-altitude operations in star hotels, large supermarkets and other industry halls and workshops. Low power consumption, no pollution, no damage to the ground during work, can be used for wall work and tapping work, work without dead ends. The single-column aluminum alloy electric lift is equipped with a gantry cross-frame attachment, which is very suitable for the maintenance work of theaters, auditoriums, churches, etc. The gantry straddle is easy to assemble, labor-saving, and flexible to move. It can cross obstacles such as fixed seats with a height of 1.1m, and can work stably on steps. It is made of high-strength rectangular steel pipe with good rigidity and stability. Equipped with universal casters, mobile and flexible. The span of the two ends of the frame is adjustable, which can be adapted to the requirements of crossing different obstacles. The two ends of the frame can be adjusted vertically, and can be used for working on slopes or steps with a certain slope. Double column ordinary style: a new generation of newly designed products, the whole is refined with high-strength aluminum profiles. Due to the high profile strength, the deflection and swing of the lifting platform are extremely small. It adopts double-mast structure, large load capacity, large platform area, excellent stability, flexible operation and convenient implementation. With its light appearance, it can exert the highest lifting capacity in a very small space. The lift is widely used in factories, hotels, buildings, shopping malls, stations, airports, stadiums, etc. It can be used for high-altitude operations such as installation and maintenance of power lines, lighting appliances, overhead pipelines, and high-altitude cleaning. Three-column aluminum alloy lift: Three groups of mast support work platforms are raised and lowered synchronously, and the supporting and retreating structure is the same as that of a single-mast platform, which has large load capacity and excellent working stability. The integral lifting guardrail device has good strength, greatly reduces the height of the whole machine during transportation, and is very convenient for loading and unloading. The assembly or disassembly can be completed by one lift. The lift has a strong carrying capacity and is suitable for two persons (which can carry certain weight tools and materials) at the same time ascending operations; it can also be customized according to different environments to various non-standard products to meet different needs. Four-pillar aluminum alloy lift: The whole is refined with high-strength aluminum profiles. Due to the high profile strength, the four-mast structure is adopted, which has excellent stability, flexible operation, large load capacity, large platform area, and convenient implementation. With its light appearance, it can exert the highest lifting capacity in a very small space. Make the deflection and swing of the lifting platform extremely small. High-altitude operations such as single-person work such as high-altitude cleaning. Multi-mast aluminum alloy lift: The whole is refined with high-strength aluminum profile. Due to the high profile strength, the four-mast structure is adopted, which has excellent stability, flexible operation, large load capacity, large platform area, and convenient implementation. With its light appearance, it can exert the highest lifting capacity in a very small space. Make the deflection and swing of the lifting platform extremely small. The lift is widely used in factories, hotels, buildings, shopping malls, stations, airports, stadiums, etc. It can be used for high-altitude operations such as installation and maintenance of power lines, lighting appliances, overhead pipelines, and high-altitude cleaning. We are the supplier of the most comprehensive aluminum alloy lift Mobile, fixed, telescopic table top, wall-mounted lift, folding lift, wall-mounted, vehicle-mounted (battery, diesel), self-propelled and other aluminum alloy lifts.According to performance, it can be divided into: 1. Mobile aluminum alloy elevator The newly designed new generation product adopts a new type of aluminum alloy profile. Due to the high strength of the profile, the deflection and swing of the lifting platform are extremely small. With its light appearance, it can exert the highest lifting capacity in a very small space. Make single-person high-altitude operations a breeze and can be moved for operations. The newly designed new generation product adopts new alloy profiles. Due to the high strength of the material, the deflection and swing of the lifting platform are extremely small. With its light appearance, it can exert the highest lifting capacity in a very small space. Make single-person high-altitude operations a breeze and can be moved for operations. 2. Fixed aluminum alloy elevator The newly designed new generation product adopts a new type of aluminum alloy profile. Due to the high strength of the profile, the deflection and swing of the lifting platform are extremely small. With its light appearance, it can exert the highest lifting capacity in a very small space. It makes it easy for one person to work at heights, and can only be fixed for work without moving. The fixed elevator is a kind of good lifting stability. It cannot be moved and can only be fixed for operation, making high-altitude operations a breeze. It is mainly used for the transportation of goods between the height difference of the production line; the on-line and off-line of materials; the height adjustment of the workpiece during the assembly of the workpiece; the feeding of the high-altitude feeder; the lifting of the parts during the assembly of large equipment; the loading and unloading of large machine tools; The site is matched with handling vehicles such as forklifts for fast loading and unloading of goods. According to the requirements of use, accessory devices can be configured for any combination, such as the safety protection device of a fixed elevator; electrical control mode; working platform form; power form, etc. The correct choice of various configurations can maximize the functions of the elevator and achieve the best use effect. The optional configuration of the fixed elevator is manual hydraulic power, movable flaps for easy connection with surrounding facilities, rolling or motorized roller table, safety touch strips to prevent rolling of feet, organ type safety shields, manual or motorized rotating workbenches , Hydraulic turning table, safety support rod to prevent the elevator from falling, stainless steel safety net, electric or hydraulic elevator walking power system, universal ball table. 3. Telescopic table top aluminum alloy lift The telescopic table lift is combined with four-wheel mobile or vehicle-mounted customization. The operation table of the platform can be freely expanded and contracted during high-altitude operations, thereby increasing the working range! Can be customized according to the actual situation of the customer. 4. Folding elevator A household foldable lift belongs to a kind of lift, especially a household foldable lift. The beam is composed of two steel plates, and they are welded and connected by a number of inverted "U"-shaped connecting cards, forming a gap in the middle, and the front and back ends are respectively placed in the track formed by the gap formed by the trolley connected by the forward and retreat motor and the electric hoist. . Therefore, the defects of unreasonable structure and inconvenient use of the existing household elevators are overcome. The utility model has the advantages of reasonable structure, simple manufacture, low cost, convenient use, strong practicability, and can be used by multiple households with one machine or used by a single household, etc. 5. Wall-mounted aluminum alloy lift It is suitable for workplaces where pits cannot be excavated. It has single collapse and double collapse. The lift is stable, safe and reliable. It is suitable for supermarkets, hospitals, restaurants, workshops and other industries. 6. Vehicle-mounted (battery, diesel) aluminum alloy lift High-altitude work equipment that installs a lift on a car. It is composed of a special chassis, a working boom, a three-dimensional full-rotation mechanism, a flexible clamping device, a hydraulic system, an electrical system, and a safety device. Special equipment for high-altitude operations refitted from elevators and battery carts. It uses the original DC power of the car engine or battery car, and can drive the lifting platform without external power supply. It is convenient to move, has a wide range of operation and flow, and the product has no pollution, no exhaust gas, large operation range, and strong fluidity. Especially suitable for cold storage, crowded areas (train stations, bus stations, airports). It is widely used in urban construction, oil field, transportation, municipal administration and other industries. According to personal requirements, safety devices such as emergency descent device, balance valve, automatic pressure maintaining, etc. can be installed in the event of power failure, safety devices to prevent overloading of high-altitude lifting platforms, leakage protection devices and phase failure protection devices, and safety explosion-proof devices to prevent hydraulic pipelines from rupturing . 7. Self-propelled aluminum alloy elevator It has walking and steering drive functions, does not require manual traction, and does not require an external power supply. It is flexible and convenient to move, making high-altitude operations more convenient and quick. It is an ideal high-altitude operation equipment for efficient and safe production of modern enterprises. It can walk fast and slowly under different working conditions, and all actions such as up and down, forward, backward, and turn can be completed continuously in the air with only one person's operation. It is especially suitable for large-scale operations such as airport terminals, stations, docks, shopping malls, stadiums, residential properties, factories and mines workshops.Product Parameters

| Mast | Type | Maximum height of platform(m) | Rated load(kg) | Supply Voltage(V) | Power(kw) | Overall Weight(kg) | Dimensions(m) |

| Single mast | SJL6-100-1 | Platform height | Load capcity | supply voltage | Power | Weight | Dimension |

| Double mast | SJL8-100-1 | 6 | 100 | 220/380 | 1.1 | 320 | 1.3×0.82×1.98 |

| Three mast | SJL10-100-1 | 8 | 100 | 220/380 | 1.1 | 320 | 1.3×0.82×1.98 |

| Four mast | SJL6-250-2 | 10 | 100 | 220/380 | 1.1 | 360 | 1.3×0.82×2.2 |

| Six mast | SJL8-250-2 | 6 | 250 | 220/380 | 1.5 | 450 | 1.55×0.85×1.65 |

| SJL10-250-2 | 8 | 250 | 220/380 | 1.5 | 560 | 1.55×0.85×2.0 | |

| SJL12-200-2 | 10 | 250 | 220/380 | 1.5 | 680 | 1.65×0.85×2.0 | |

| SJL14-200-2 | 12 | 200 | 220/380 | 1.5 | 720 | 1.65×0.85×2.0 | |

| SJL10-250-3 | 14 | 200 | 220/380 | 1.5 | 780 | 1.55×0.85×2.5 | |

| SJL12-250-3 | 10 | 250 | 220/380 | 1.5 | 1080 | 1.88×1.0×2.05 | |

| SJL14-200-3 | 12 | 250 | 220/380 | 1.5 | 1160 | 1.88×1.0×2.05 | |

| SJL16-200-3 | 14 | 200 | 220/380 | 2.2 | 1060 | 1.9×1.2×2.5 | |

| SJL12-250-4 | 16 | 200 | 220/380 | 2.2 | 1120 | 2×1.2×2.5 | |

| SJL14-200-4 | 12 | 250 | 220/380 | 2.2 | 1050 | 1.95×1.2×20 | |

| SJL16-200-4 | 14 | 200 | 220/380 | 2.2 | 1250 | 1.9×1.2×2.5 | |

| SJL18-250-4 | 16 | 200 | 220/380 | 2.2 | 1480 | 2×1.2×2.5 | |

| SJL18-160-6 | 18 | 250 | 220/380 | 2.2 | 1700 | 2.15×1.35×2.96 | |

| SJL20-160-6 | 16 | 160 | 220/380 | 2.2/1.5 | 1450 | 2.1×1.2×2.1 | |

| SJL22-160-6 | 20 | 160 | 220/380 | 2.2/1.5 | 1520 | 2.26×1.4×2.3 | |

| SJL24-160-6 | 22 | 160 | 220/380 | 2.2/1.5 | 1880 | 2.26×1.4×2.5 | |

| 24 | 160 | 220/380 | 2.2/1.5 | 1980 | 2.26×1.4×2.7 |